Hydrogen vapour permeability is a critical factor in many industries, particularly those involving the storage, transportation, and utilization of hydrogen gas. Here are the key points highlighting its relevance:

Hydrogen vapour permeability is a critical factor in many industries, particularly those involving the storage, transportation, and utilization of hydrogen gas. Here are the key points highlighting its relevance:

Hydrogen Storage and Transport:

The permeability of materials to hydrogen vapour is crucial when selecting materials for hydrogen storage tanks and pipelines. High permeability can lead to hydrogen loss and potential safety hazards. The selection of materials with appropriate permeabilities for storage and pipeline is a critical tool in the battle against the embrittlement hydrogen causes these containers.

Ensuring low hydrogen permeability is essential in preventing Hydrogen leakage which can lead to explosions or other safety issues, given its flammability. The effective containment of hydrogen in storage systems is necessary to maintain efficiency and economic viability.

Fuel Cells:

In proton exchange membrane (PEM) fuel cells, the membrane must have a low hydrogen permeability to prevent cross-over from the anode to the cathode, which reduces efficiency and damage the cell. Once again materials with low hydrogen permeabilities are more durable which makes the use of fuel cells more cost effective.

Hydrogen Production:

During hydrogen production, especially via electrolysis or reforming. Low vapour permeability are membranes ensure purity and efficiency of the hydrogen production process. Additionally, the catalysts used in the process need to be protected from hydrogen permeation, which can degrade their performance over time.

Cryogenics:

Low vapour permeability materials reduce hydrogen losses through insulation materials, ensuring the safety and efficiency in cryogenic applications.

Automotive:

Automotive:

Vehicles powered by hydrogen fuel cells require tanks with very low hydrogen permeability to prevent loss, embrittlement and to and ensure safety.

Aerospace:

Hydrogen is frequently used as rocket fuel by the aerospace industry. Ensuring that storage materials have low hydrogen permeability is critical to avoid leaks and maintain fuel integrity.

Energy Infrastructure:

For the emerging hydrogen economy, pipelines transporting hydrogen must be made from materials with low permeability for safety, to prevent losses and minimise degradation in the supply network.

Petrochemical:

Hydrogen is used extensively in refining and petrochemical processes. Equipment and infrastructure must be designed to handle hydrogen with low permeability to maintain operational integrity.

Glass Manufacturing:

Glass Manufacturing:

In industries such as glass manufacturing, where hydrogen is used in the production process, materials with low permeability help in maintaining the necessary hydrogen atmosphere.

Medical Gas Storage and Delivery Systems:

Though not as common as oxygen or other medical gases, hydrogen is sometimes used in medical research and therapy, particularly in experimental treatments. Ensuring that storage and delivery systems for hydrogen have low permeability is crucial to prevent leaks and ensure accurate dosage delivery.

Hydrogen vapour permeability helps ensure safety, functionality, and longevity. From storage systems to implantable devices and sterilization processes, materials with appropriate permeability characteristics are essential for maintaining the reliability and effectiveness of medical technologies

Hydrogen Peroxide Sterilization: Hydrogen peroxide is often used for sterilizing equipment. While not the same as hydrogen gas, ensuring that materials have appropriate permeability properties can help manage the interaction with sterilizing agents and prevent unwanted reactions or material degradation.

Electronics and Sensors:

Many devices contain sensitive electronics and sensors that need to be protected from gases, including hydrogen. Ensuring that casings and housings are made from materials with low hydrogen permeability helps protect these components and maintain device

Hydrogen vapour permeability is a fundamental consideration across various industries, impacting the safety, efficiency, and economic viability of hydrogen-related technologies and processes. As the hydrogen economy grows, the development of materials with optimal permeability characteristics will be increasingly critical.

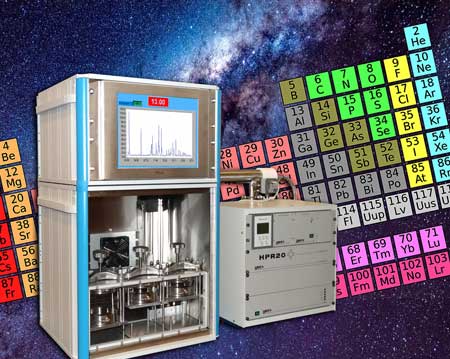

To find out more about Hydrogen Permeability testing click here

For equipment to measure permeability click here

For the Wikipedia article on hydrogen click here